What is Sandblasting?

Sandblasting is a technique used to clean and smooth surfaces by blasting them with abrasive materials at high speeds. This method is highly effective in removing dirt, paint, and other contaminants from surfaces, making it a popular choice for restoring brick fireplaces. The process involves the use of a sandblasting machine, which propels fine particles of abrasive material, such as sand or glass beads, onto the surface at high pressure. The impact of these particles against the surface removes the unwanted layers, revealing a clean and fresh appearance underneath.

Sandblasting can be used on various materials, including metal, wood, and brick. For brick fireplaces, it is particularly beneficial because it can effectively remove years of soot, grime, and paint without causing significant damage to the brick itself. However, it is important to use the correct type of abrasive material and pressure settings to avoid damaging the brickwork.

The technique was first developed in the late 19th century and has since evolved with advancements in technology and materials. Modern sandblasting equipment allows for precise control over the pressure and type of abrasive used, making it a versatile and efficient method for surface preparation and cleaning.

While sandblasting is an effective cleaning method, it requires proper safety precautions due to the high pressure and abrasive materials involved. Protective gear, such as goggles, gloves, and respiratory protection, is essential to prevent injury and inhalation of dust particles. Additionally, proper ventilation and containment measures should be in place to minimize the spread of dust and debris.

In summary, sandblasting is a powerful technique for cleaning and restoring brick fireplaces, offering a thorough and efficient solution for removing accumulated grime and paint. With proper safety measures and equipment, it can significantly enhance the appearance and longevity of a brick fireplace.

Benefits of Sandblasting a Brick Fireplace

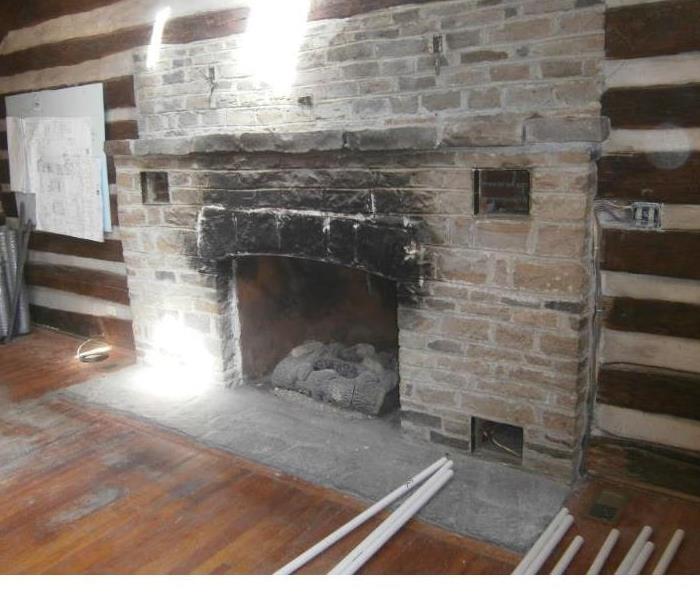

Sandblasting offers several benefits when it comes to cleaning and restoring brick fireplaces. One of the primary advantages is its effectiveness in removing stubborn dirt, soot, and paint. Traditional cleaning methods, such as scrubbing with brushes or using chemical cleaners, can be time-consuming and may not achieve the desired level of cleanliness. Sandblasting, on the other hand, can quickly and efficiently strip away layers of buildup, revealing the original brick surface.

Another benefit is the ability to restore the aesthetic appeal of the fireplace. Over time, brick fireplaces can become discolored and stained from smoke and heat. Sandblasting can remove these unsightly marks, making the fireplace look new again. This can enhance the overall appearance of the room and increase the value of the property.

Sandblasting is also a versatile technique that can be tailored to the specific needs of the project. Different types of abrasive materials and pressure settings can be used to achieve the desired result without damaging the brick. For example, finer abrasives and lower pressure settings can be used for delicate brickwork, while coarser materials and higher pressures can be used for more robust cleaning.

In addition to improving the appearance of the fireplace, sandblasting can also enhance its functionality. Removing layers of soot and grime can improve the efficiency of the fireplace, allowing it to burn more cleanly and efficiently. This can reduce the amount of smoke and pollutants released into the air, creating a healthier indoor environment.

Furthermore, sandblasting can help prepare the fireplace for further treatment or restoration work. For example, once the surface has been cleaned, it can be easier to apply sealants, paints, or other protective coatings. This can help to preserve the condition of the brick and extend the life of the fireplace.

Overall, sandblasting is a highly effective and versatile method for cleaning and restoring brick fireplaces. Its ability to remove stubborn dirt and stains, enhance the appearance and functionality of the fireplace, and prepare the surface for further treatment makes it a valuable tool in fireplace maintenance and restoration.

Equipment and Materials Needed for Sandblasting

To successfully sandblast a brick fireplace, having the right equipment and materials is crucial. The primary piece of equipment needed is a sandblasting machine, which typically consists of a compressor, a blasting pot, and a nozzle. The compressor generates the air pressure required to propel the abrasive material through the blasting pot and out of the nozzle at high speed.

Choosing the right type of abrasive material is also important. Common abrasives used for sandblasting include silica sand, glass beads, aluminum oxide, and crushed walnut shells. Each type of abrasive has its characteristics and is suitable for different applications. For brick fireplaces, a softer abrasive such as crushed walnut shells or glass beads is often preferred to avoid damaging the brick surface.

Protective gear is essential for the safety of the operator. This includes a full-face respirator or helmet with a fresh air supply, heavy-duty gloves, long-sleeved clothing, and ear protection. The high-speed particles can cause serious injury if they come into contact with the skin or eyes, and inhaling dust particles can be harmful to the lungs.

In addition to the sandblasting equipment and protective gear, other materials needed for the project include plastic sheeting or tarps to protect surrounding areas from dust and debris, painter’s tape to secure the plastic sheeting, and a broom or vacuum to clean up the workspace after sandblasting.

It’s also helpful to have a moisture separator or air dryer attached to the compressor. This prevents moisture from mixing with the abrasive material, which can cause clumping and reduce the effectiveness of the sandblasting process. Moisture in the air supply can also lead to rust and other damage to the equipment.

Proper setup and maintenance of the equipment are essential for a successful sandblasting project. Regularly checking and replacing worn parts, such as nozzles and hoses, can prevent breakdowns and ensure consistent performance. It’s also important to follow the manufacturer’s instructions for operating the equipment and to conduct a thorough inspection of the work area before starting the project.

Interesting Articles You May Want to Check:

Preparing the Fireplace for Sandblasting

Proper preparation is key to a successful sandblasting project. The first step in preparing a brick fireplace for sandblasting is to remove any furniture, decor, or other items from the surrounding area to protect them from dust and debris. Cover any remaining items and the floor with plastic sheeting or tarps, and secure the edges with painter’s tape to prevent dust from escaping.

Next, inspect the fireplace for any loose or damaged bricks. Sandblasting can further weaken these areas, so it’s important to repair any structural issues before starting the project. This may involve repointing the mortar joints, replacing damaged bricks, or reinforcing the structure with additional support.

Once the fireplace is structurally sound, it’s time to protect any areas that should not be sandblasted. This includes surrounding walls, mantels, and any decorative elements that are part of the fireplace. Use painter’s tape and plastic sheeting to cover these areas, ensuring a secure and tight seal to prevent dust from entering.

Before beginning the sandblasting process, ensure that the room is well-ventilated. Open windows and doors, and use fans to create a cross-ventilation system that will help to remove dust and fumes from the work area. If possible, set up an air filtration system to capture airborne particles and improve air quality during the project.

With the work area prepared and protected, the next step is to set up the sandblasting equipment. Follow the manufacturer’s instructions for assembling the machine, connecting the air compressor, and filling the blasting pot with the chosen abrasive material. Conduct a test run on a small, inconspicuous area of the fireplace to ensure that the pressure settings and abrasive material are appropriate for the brick surface.

Finally, don all necessary protective gear, including a full-face respirator or helmet, gloves, long-sleeved clothing, and ear protection. Safety is paramount when sandblasting, as the high-speed particles can cause serious injury if proper precautions are not taken. Double-check all equipment and safety measures before proceeding with the sandblasting process.

The Sandblasting Process

The sandblasting process itself involves several key steps, each of which must be carried out with care and precision to achieve the best results. Begin by positioning yourself at a safe distance from the fireplace, holding the sandblasting nozzle at a slight angle to the surface. This angle helps to minimize direct impact on the bricks and allows the abrasive material to effectively remove dirt and contaminants.

Start the sandblasting machine and gradually increase the pressure to the desired level. It’s important to start with a lower pressure setting and adjust as needed, especially when working with delicate brick surfaces. Too much pressure can damage the bricks or mortar, while too little pressure may not effectively remove the buildup.

Move the nozzle in a consistent, sweeping motion, working in small sections at a time. This ensures even coverage and prevents over-concentration of the abrasive material in one area. Maintain a steady pace and avoid lingering too long on any one spot, as this can cause uneven wear and damage to the bricks.

As you progress, periodically stop to inspect the surface and assess the effectiveness of the sandblasting. If necessary, adjust the pressure settings or switch to a different type of abrasive material to achieve the desired results. Be mindful of any areas that may require extra attention, such as heavily stained or painted sections.

Throughout the sandblasting process, ensure that the workspace remains clean and free of excess dust and debris. Use a broom or vacuum to periodically clean the area, and check the plastic sheeting and tape to ensure they remain securely in place. Maintaining a clean work environment helps to improve visibility and prevent dust from spreading to other areas of the home.

Once the entire surface has been sandblasted to your satisfaction, turn off the machine and allow the area to settle for a few minutes. Carefully remove the plastic sheeting and painter’s tape, and dispose of any debris according to local regulations. Perform a final inspection of the fireplace to ensure that all areas have been adequately cleaned and that no damage has occurred during the process.

Post-Sandblasting Cleanup and Maintenance

After completing the sandblasting process, thorough cleanup is essential to remove any remaining dust and debris. Begin by vacuuming the entire area, including the floor and surrounding surfaces, to capture loose particles. Use a vacuum with a HEPA filter to ensure that fine dust is effectively removed and does not recirculate into the air.

Next, wipe down the brick surface with a damp cloth or sponge to remove any residual abrasive material. This step helps to reveal the final appearance of the bricks and ensures that no abrasive particles remain embedded in the surface. Allow the bricks to dry completely before proceeding with any additional treatments or maintenance.

Inspect the fireplace for any areas that may require further attention, such as small sections that were missed during the sandblasting process or areas where the abrasive material may have caused slight damage. Address these issues as needed, using appropriate repair techniques or additional cleaning methods.

If desired, apply a sealant or protective coating to the brick surface to help preserve its appearance and protect it from future damage. Choose a product that is specifically designed for use on brick and follow the manufacturer’s instructions for application. This step can help to extend the life of the fireplace and maintain its clean, restored appearance.

Regular maintenance is important to keep the fireplace looking its best and functioning properly. Perform routine cleaning to remove soot and grime buildup, and inspect the bricks and mortar for any signs of damage or wear. Address any issues promptly to prevent further deterioration and maintain the structural integrity of the fireplace.

In addition to regular cleaning, consider having the fireplace professionally inspected and serviced on a regular basis. A professional can identify and address any underlying issues, such as cracks or structural weaknesses, and provide recommendations for ongoing maintenance and care.

Common Mistakes to Avoid

Using the Wrong Abrasive Material

Selecting the appropriate abrasive material is crucial for successful sandblasting. A common mistake is using an abrasive that is too coarse or too harsh for the brick surface. This can result in damage to the bricks, such as chipping or erosion. On the other hand, using an abrasive that is too fine may not effectively remove the buildup of dirt, soot, and paint, leading to unsatisfactory results. It is important to choose an abrasive that is specifically suited for brick surfaces, such as crushed walnut shells or glass beads, to achieve the desired cleaning effect without causing harm.

Inadequate Preparation of the Work Area

Proper preparation of the work area is essential to prevent damage and ensure a successful sandblasting project. A common mistake is neglecting to cover surrounding surfaces and items, which can result in a significant mess and potential damage to furniture and decor. Using plastic sheeting or tarps to cover the floor, walls, and any remaining items in the vicinity is necessary to contain dust and debris. Securing the edges of the sheeting with painter’s tape helps to prevent dust from escaping and spreading to other areas of the home.

Insufficient Safety Precautions

Sandblasting involves high-pressure equipment and abrasive materials that can cause serious injury if not handled properly. A common mistake is failing to take adequate safety precautions. Always wearing appropriate protective gear, such as a full-face respirator, heavy-duty gloves, long-sleeved clothing, and ear protection, is essential to prevent injury. Ensuring that the work area is well-ventilated by opening windows and doors and using fans to create cross-ventilation is also important to minimize the inhalation of dust and fumes.

Using Excessive Pressure

Applying too much pressure during sandblasting is a mistake that can cause irreversible damage to the brick surface. Starting with a lower pressure setting and adjusting as needed based on the condition of the brick and the effectiveness of the cleaning is important. Excessive pressure can erode the brick and mortar, resulting in a weakened structure and unsightly appearance. It is better to start with lower pressure and gradually increase it until the desired cleaning effect is achieved.

Neglecting Post-Sandblasting Cleanup and Maintenance

Thorough post-sandblasting cleanup and maintenance are essential to preserve the appearance and functionality of the fireplace. A common mistake is neglecting these steps. After sandblasting, vacuuming the entire area, including the floor and surrounding surfaces, to capture loose particles is necessary. Wiping down the brick surface with a damp cloth or sponge to remove any residual abrasive material helps to reveal the final appearance of the bricks. Regular maintenance, such as routine cleaning and inspection of the bricks and mortar for any signs of damage or wear, is also important to keep the fireplace in good condition.

What type of abrasive material is best for sandblasting a brick fireplace?

The best type of abrasive material for sandblasting a brick fireplace depends on the condition of the brick and the desired outcome. Softer abrasives, such as crushed walnut shells or glass beads, are often preferred because they effectively remove dirt and paint without causing significant damage to the brick surface. These materials are gentle enough to clean the brick while preserving its integrity. It is important to avoid using overly coarse or harsh abrasives, such as silica sand, as they can erode the brick and mortar, leading to structural damage.

How should I prepare my brick fireplace for sandblasting?

Proper preparation of the brick fireplace and surrounding area is essential for a successful sandblasting project. Begin by removing any furniture, decor, or other items from the vicinity to protect them from dust and debris. Cover any remaining items and the floor with plastic sheeting or tarps, and secure the edges with painter’s tape. Inspect the fireplace for any loose or damaged bricks, and repair any structural issues before starting the sandblasting process. Protect areas that should not be sandblasted, such as surrounding walls and mantels, by covering them with plastic sheeting and securing it with tape.

What safety precautions should I take when sandblasting a brick fireplace?

Sandblasting involves high-pressure equipment and abrasive materials, making safety precautions essential. Always wear appropriate protective gear, including a full-face respirator or helmet with a fresh air supply, heavy-duty gloves, long-sleeved clothing, and ear protection. Ensure the work area is well-ventilated by opening windows and doors and using fans to create cross-ventilation. Additionally, use plastic sheeting to contain dust and debris and prevent it from spreading to other areas of the home. Following these safety measures helps to prevent injury and minimize health hazards.

How can I avoid damaging the brick surface during sandblasting?

To avoid damaging the brick surface during sandblasting, start with a lower pressure setting and gradually increase it as needed. This approach helps to prevent excessive erosion of the brick and mortar. Choose a softer abrasive material, such as crushed walnut shells or glass beads, which are less likely to cause damage. Maintain a consistent, sweeping motion with the sandblasting nozzle, and avoid lingering too long on any one spot. Periodically inspect the surface to assess the effectiveness of the sandblasting and make adjustments as necessary.

What should I do after sandblasting my brick fireplace?

After sandblasting, thorough cleanup is essential to remove any remaining dust and debris. Begin by vacuuming the entire area, including the floor and surrounding surfaces, to capture loose particles. Wipe down the brick surface with a damp cloth or sponge to remove any residual abrasive material. Inspect the fireplace for any areas that may require further attention, such as small sections that were missed during the sandblasting process or areas where the abrasive material may have caused slight damage. Consider applying a sealant or protective coating to the brick surface to help preserve its appearance and protect it from future damage. Regular maintenance, such as routine cleaning and inspection, is also important to keep the fireplace in good condition.

Related Posts:

- Rock Over Brick Fireplace: A Fusion Of Rustic Charm And Modern Efficiency

- Covering Brick Fireplace with Stone Veneer

- Lining a Fireplace with Fire Brick

- How to Clean a Brick Fireplace with Muriatic Acid

- Acid Wash Brick Fireplace

- Marble Over Brick Fireplace

- Brick Fireplace Glass Doors

- Brick Fireplace Vents

- Outside Brick Fireplace Designs

- Open Brick Fireplace